Blog Nitronic Austenitic Stainless Steel Material Profile

November 25, 2020

By: Dave Olsen

Grade

- Nitronic® 50 (J93790 / CG6MMN / Licensed by Armco, Inc.)

Description

- Low carbon austenitic stainless steel

Nitronic 50 Material Properties – Why select this material

- The most corrosion resistant alloy in the Nitronic family.

- Mechanical properties and corrosion resistance are superior to published values for CF8/304 and CF8M/316.

- Excellent performance in acidic, chloride and hydrogen sulfide environments.

- Good strength and ductility from high temperature to cryogenic.

Applications – Frequent Uses

- Chemical processing

- Marine environments

- Sour gas well services

- Oilfield equipment

Grade

- Nitronic® 60 (J92972 / CF10SMnN / Licensed by Armco, Inc.)

Description

- Austenitic stainless steel for elevated temperatures

Nitronic 60 Properties – Why select this material

- The 4% nominal silicon content improves high temperature corrosion and oxidation resistance.

- Mechanical properties and corrosion resistance are superior to published values for CF8/304 and CF8M/316.

- Excellent wear resistance of the alloy in metal to metal contact applications.

- Good strength and ductility from high temperature to cryogenic.

Applications – Frequent Uses

- Gas turbine

- Higher temperature industrial applications.

For guidance in selecting the appropriate austenitic stainless steel in your application, contact us.

Have questions?

Download Our Alloy Guide

Download Our Where Used Guide

Blog Tags

Related Blogs

Sand Casting vs. Investment Casting for Pump Impellers: Which Process is Right for You?

When it comes to manufacturing pump impellers, choosing the right casting process is critical. Two widely used metal...

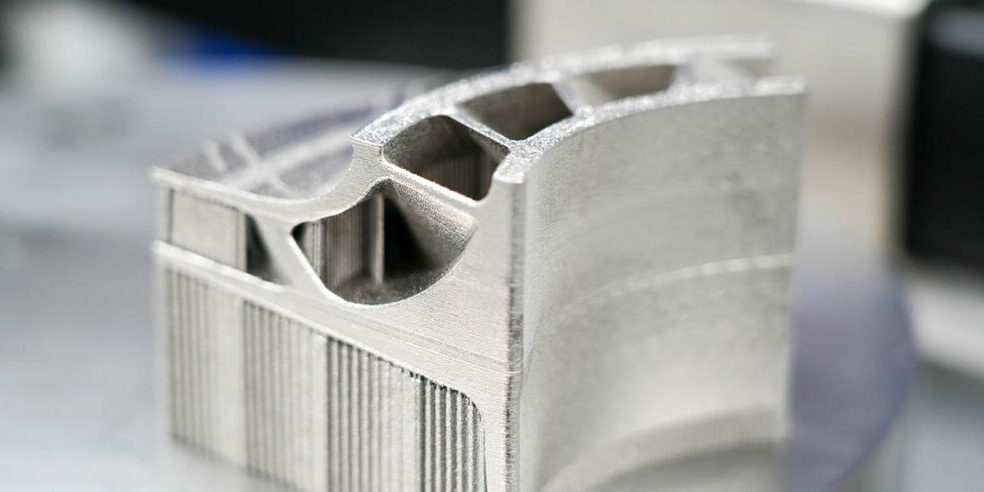

Investment Casting vs. CNC vs. 3D Printing: The Best Way To Make Pump Impellers

When it comes to pump impeller manufacturing, manufacturers evaluate several production methods including CNC machining, investment casting, and...

Additive Manufacturing vs. Casting: When to Use Each

In the world of manufacturing metal components, choosing the right method is crucial. Additive manufacturing and casting are...